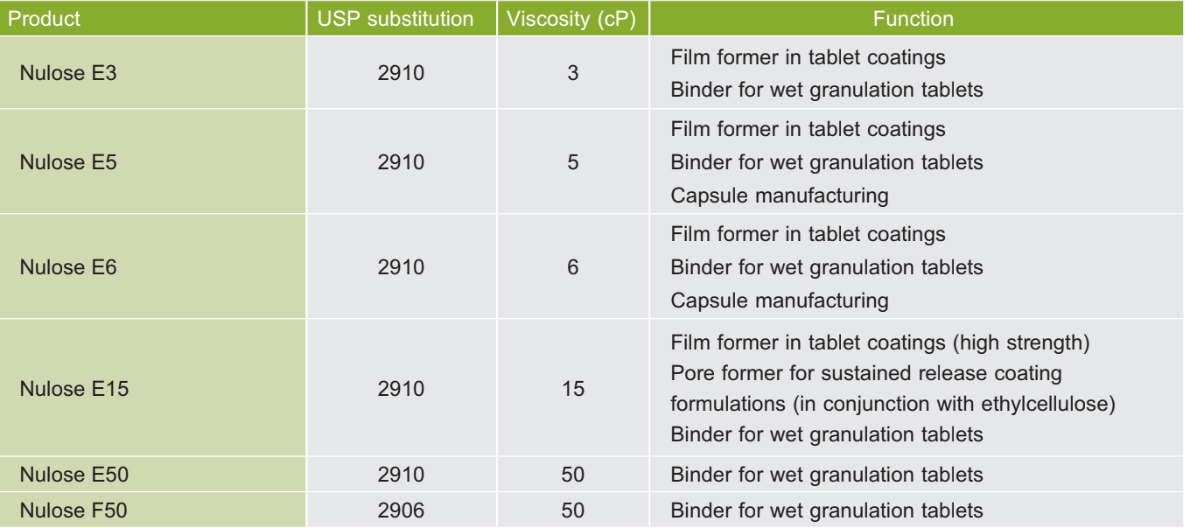

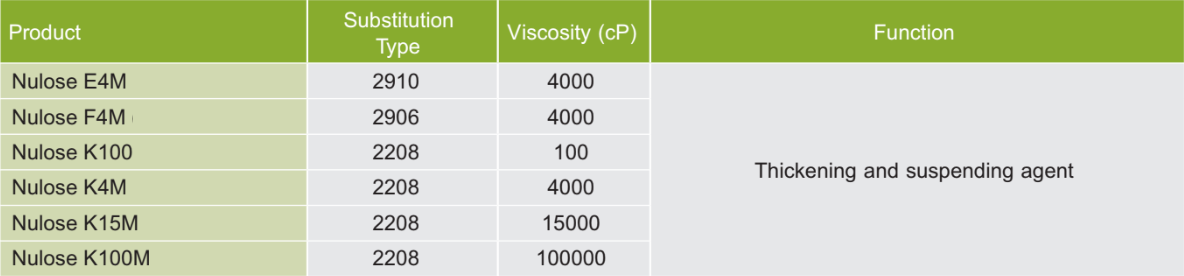

Nulose HPMC are high-functionality excipients used mainly as binders, thickeners, dispersants, emulsifiers, film formers, and suspending agents. Nulose HPMC is effective for film coatings, vegetarian capsules, and controlled-release applications.

For food and cosmetics applications, Nulose HPMC can act as a film former, thickener, binder, humectant, and thermal gelation agent to improve stability, texture, and sensory.